Materials

Enjoy the broadest range of materials available on a desktop system, all at your fingertips, including:

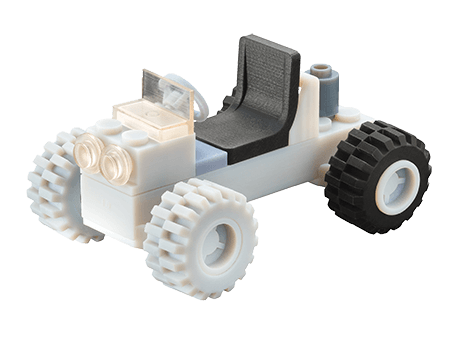

- Rigid Opaque (Vero family) in a variety of colors including white, gray, blue and black

- Transparent (RGD720 and VeroClear) for clear and tinted products with great dimensional stability and surface smoothness

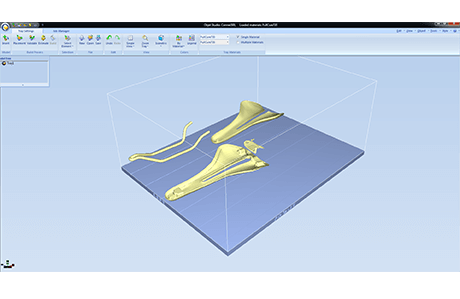

- High Temperature (RGD525) for advanced functional testing, hot air and water flow, and static applications

- Simulated Polypropylene materials (RGD450 & RGD430) with toughness and durability for smooth prototypes with living hinges, flexible closures and snap-fit parts

- Rubber-like materials (Tango Gray or Tango Black) for a range of applications requiring non-slip or soft surfaces

- Bio-compatible (MED610) for medical-device prototyping